The processing of coffee, both as beans and as a ground blend, poses particular challenges for pneumatic conveying systems. However, the latest technology allows these to be overcome and coffee to be conveyed around the processing system efficiently.

A vacuum conveyor system is used to send the coffee along the conveying line, and it’s important that this line is of an appropriate size for the system with which it connects. If whole beans are being moved, the velocity of the conveying line must not be so high that it damages the beans. With ground coffee, there is a different challenge: the different sizes of particle in the blend must not be allowed to separate while the coffee is moving down the line.

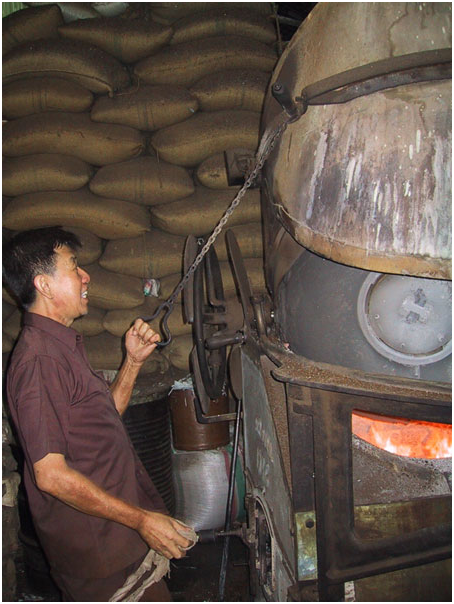

Just to add interest to the process, coffee is an abrasive substance, so equipment that can resist abrasion must be used.

Preserving the integrity of the blend

A vacuum conveyor such as http://www.aptech.uk.com/pneumatic-conveying/vacuum-conveying/ can help move the coffee to a filling machine without damage, without blends becoming separated into their constituent parts, and without contamination between different flavours or blends. Pneumatic conveying systems have also become the preferred method for moving any finished product from the manufacturing line to the packaging line.

When the coffee arrives at the facility in a bulk bag, it is emptied into a receiving hopper. This forces out the air inside the hopper. The air must go through a filter and dust collector; otherwise, airborne particles of coffee can escape. The filter can trap the coffee dust and a pneumatic pulse can then push it back into the receiving hopper. This greatly reduces the amount of time needed to perform cleaning.

Ground coffee is trickier to convey

Coffee beans tend to be free-flowing, so they will pass along the processing equipment without too much trouble. Ground coffee is trickier. It tends to get caught in the hoppers, stopping a free flow of coffee into the processing equipment. In some plants, mechanical agitators are used in the hoppers to loosen any coffee that has become interlocked.

Sometimes coffee arrives packed in smaller bags that need to be broken. This process must include filters, a dust hood and a pneumatic cleaner. A screen over the receiving vessel provides a safer environment for the operators.